-

Your shopping cart is empty!

MENU

- Home +

-

Brake Lines

+

ABS DOT Brake Lines

Hi-Performance Aramid Fiber Construction

Harley-Davidson ABS DOT Brake Lines

Dual Disc Single Disc Dual to Single Conversion Rear Kits

Indian ABS DOT Brake Lines

Universal

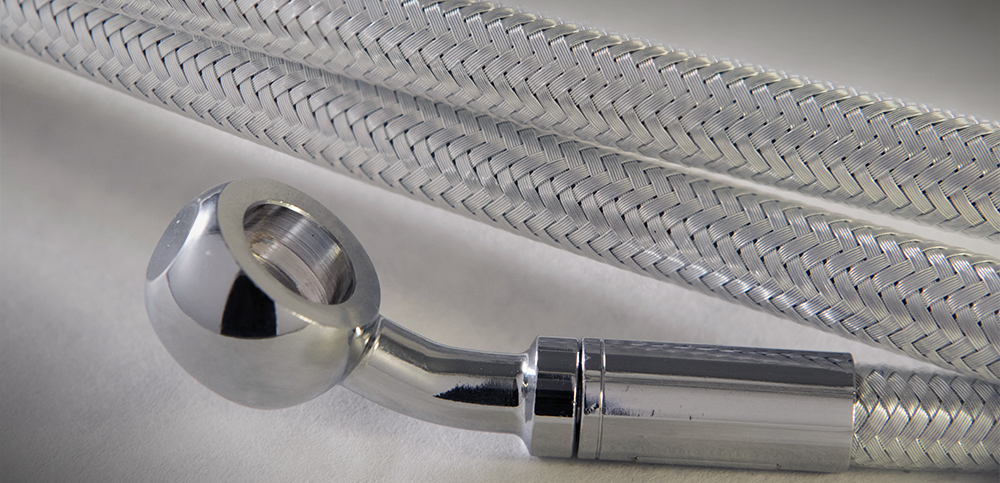

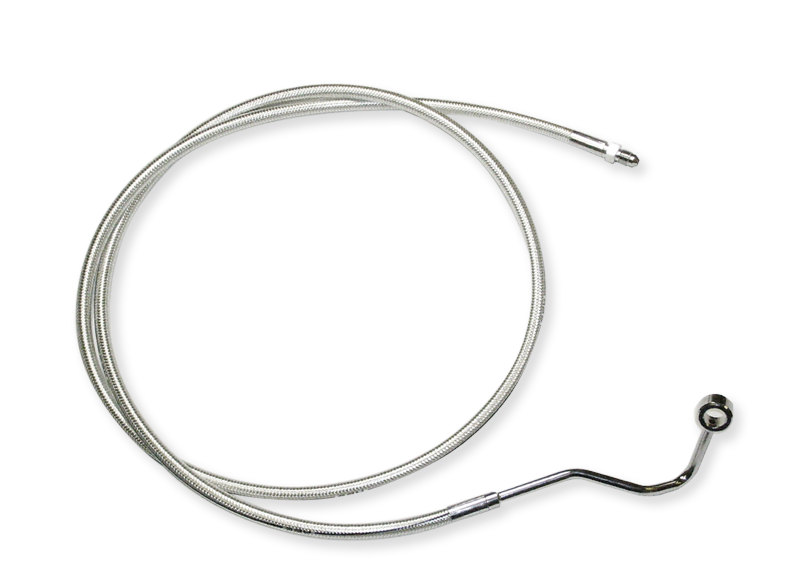

Stainless Steel Construction

Harley-Davidson ABS DOT Brake Lines

Dyna, Sportster, & Softail Complete ABS Kits Touring & Softail ABS LowersTouring & Softail ABS UppersWHY ARAMID FIBER VS.

STAINLESS STEEL?High quality brake lines are commonly made of stainless steel braided over PTFE tubing. This is the most economical way to produce a performance brake line for automotive applications.

For those who are looking for a higher standard relative to performance, looks, and safety, braided aramid fiber covered with one of our signature braids is the answer.

Non-ABS DOT Brake Lines

Hi-Performance Aramid Fiber Construction

Harley-Davidson Non-ABS DOT Brake Lines w/ manifold

EZ-Align DOT Brake Lines

Harley-Davidson

Single DiscIndian

Single DiscVictory

Universal DOT Brake Lines

Universal Braided with -3AN Fittings

Stainless Steel Construction

XR Stainless Non-ABS DOT Brake Lines

WHY ARAMID FIBER VS.

STAINLESS STEEL?High quality brake lines are commonly made of stainless steel braided over PTFE tubing. This is the most economical way to produce a performance brake line for automotive applications.

For those who are looking for a higher standard relative to performance, looks, and safety, braided aramid fiber covered with one of our signature braids is the answer.

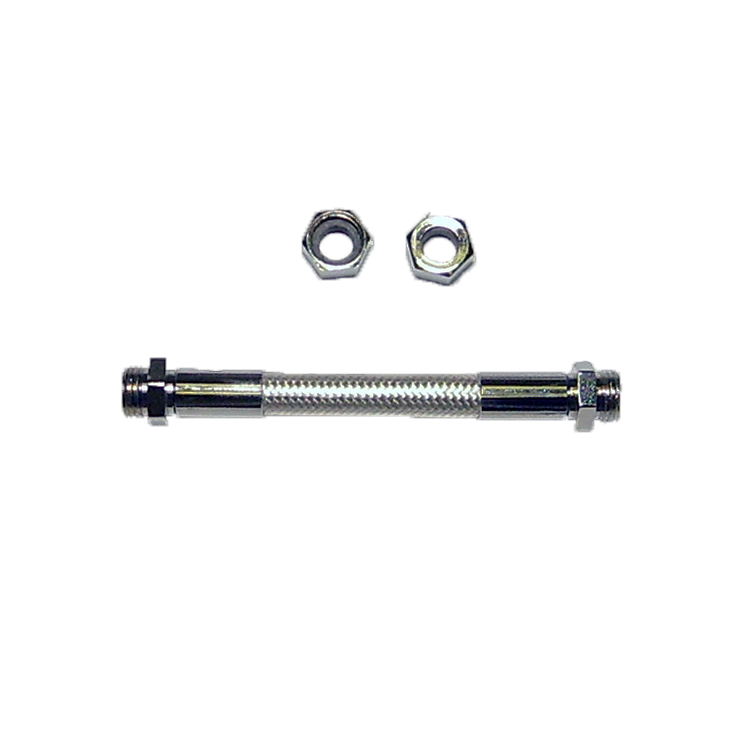

BYO "Build-Your-Own" DOT Products

Adapters, Banjos, Accessories

-

Control Cables

+

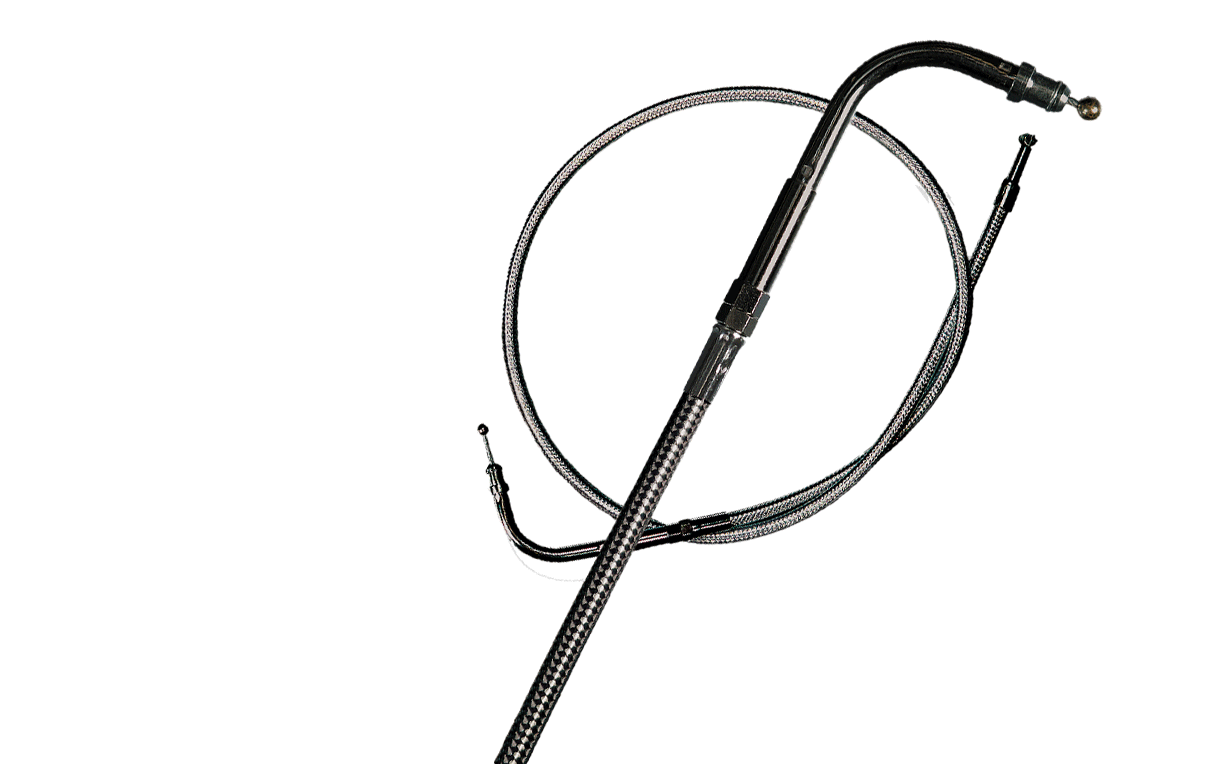

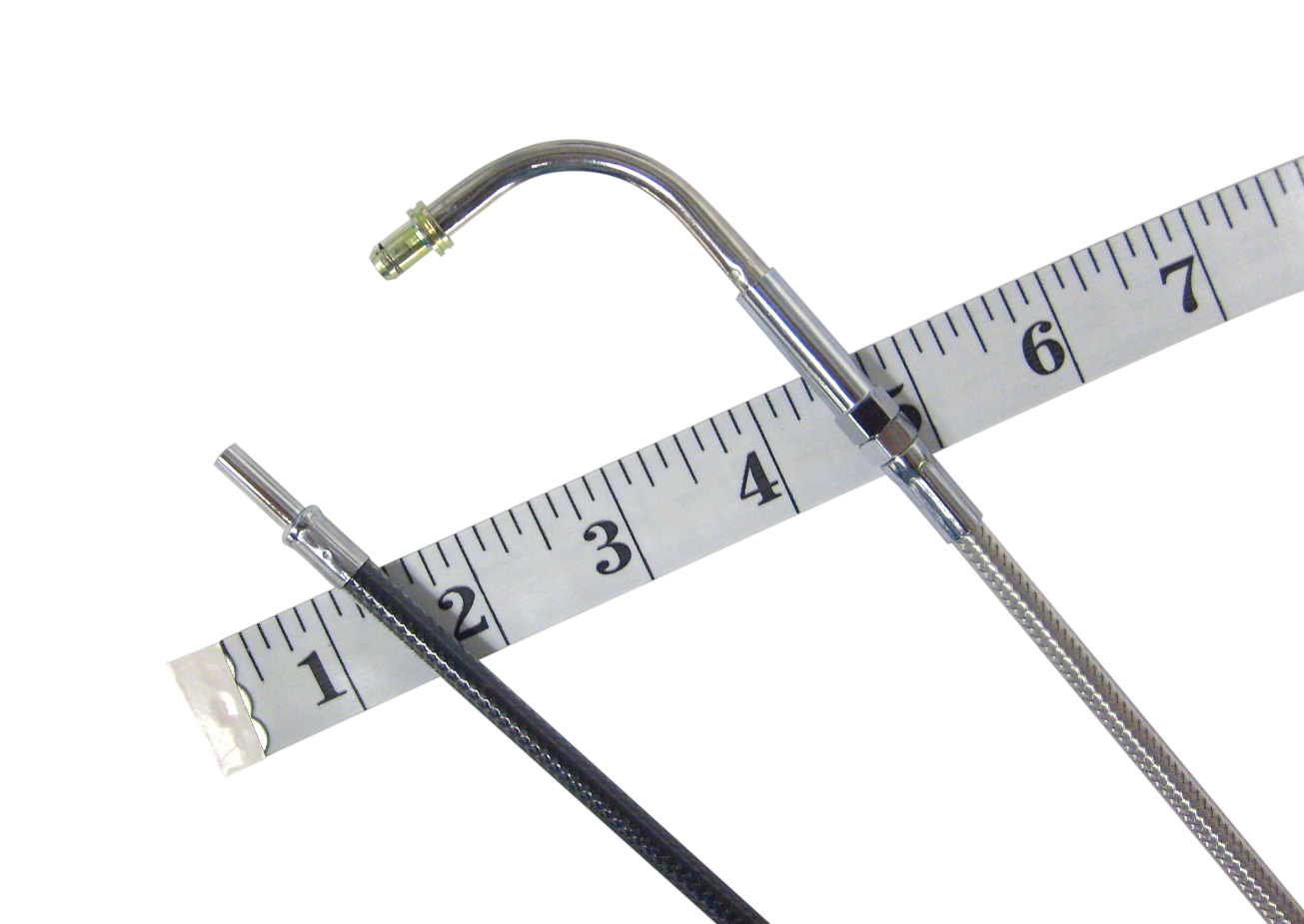

Clutch Cables & Lines

Harley-Davidson

Quick Connect Upper Clutch Cables

Victory

Clutch CablesIndian

Clutch CablesMetric

Clutch CablesBYO® “Build-Your-Own”

Throttle/Idle/Idle-Cruise Cables

Harley-Davidson

Victory

Metric

BYO® “Build-Your-Own”

-

Handlebars/Install Kits

+

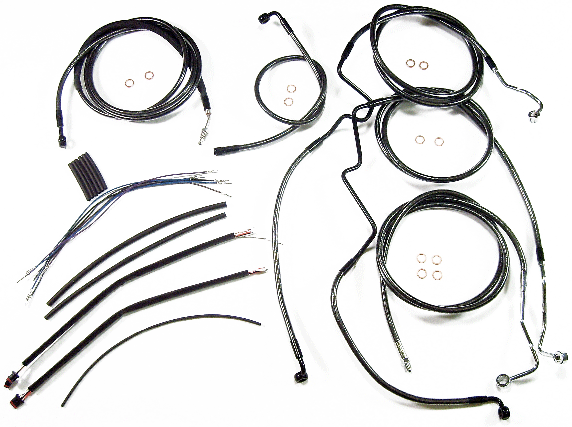

Handlebar Installation Kits

Hi-Performance Aramid Fiber Construction

Stainless Steel Construction

Magnum Handlebars with Kits

Magnum Handlebars

-

Custom Orders

+

-

Other

+